Products Description

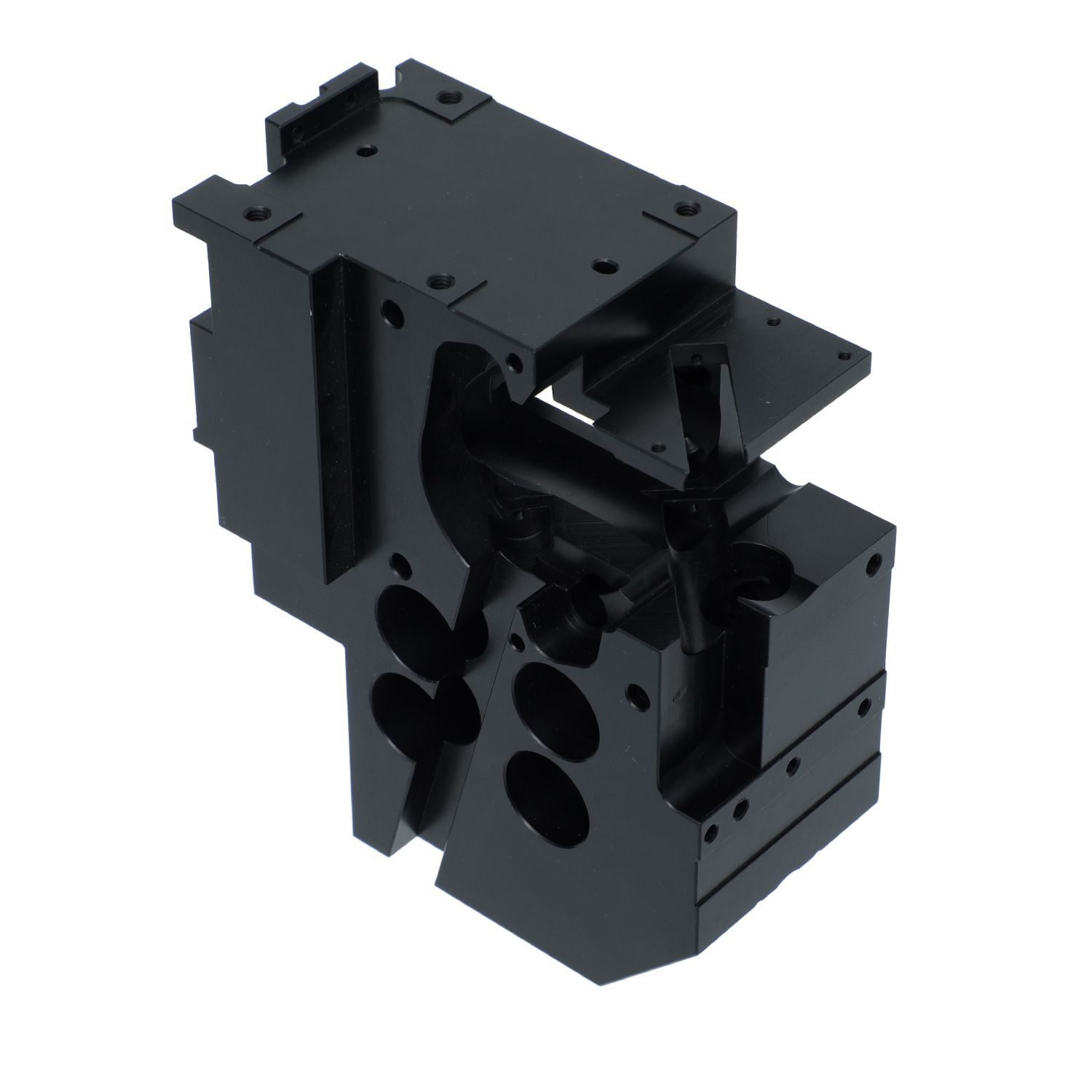

The following analysis of this part considers its material, structure, function, and processing technology:

一、Material:

Based on its appearance, texture, color, and precision machining characteristics, the material is presumably black POM (Polymer Oxide).

This type of material possesses good machinability, insulation, and a certain level of strength, making it suitable for structural support or functional integration

components in precision equipment.

二、Structure and Function:

This part exhibits a complex, blocky structure with multiple interfaces and chambers, functioning as a "modular integration carrier" for precision equipment:

Multiple circular holes (including threaded holes and open holes) on the surface are used to assemble other components (such as motors, sensors, and pipelines);

The hollow and grooved design accommodates internal functional modules (such as circuits and transmission components) or allows for the passage of pipelines;

The overall rigid structure enables precise positioning and connection of multiple components, ensuring the assembly accuracy and operatio stability of the equipment.

三、Manufacturing Process

The manufacturing process reflects precision manufacturing capabilities:

CNC Precision Machining:

Complex shapes, holes, and cavities are formed through CNC milling, ensuring hole coaxiality and dimensional tolerances reach precision level ≤0.05mm;

Surface Treatment:

The plastic surface retains its original black color after milling, with a high surface finish Ra≤3.2μm, free of obvious burrs, ensuring assembly compatibility;

Quality Inspection:

Hole accuracy and structural strength (such as the tensile strength of threaded holes) are tested to ensure no deformation or breakage occurs during equipment

operation.

四、Application Scenarios

Combined with the structure's "multi-interface, modular integration" characteristics, this part is used in optical equipment (such as lens module brackets) to play a core role in "multi-component integration, precise positioning, and insulation protection," ensuring the equipment's compactness and reliability.

Contact Us

Technical Support: +86 150-1532-6863

Email: cassy@xqdmachining.com

Website: https://xqdmachining.com/index.html