Products Description

ISO9001 certified medical CNC machined parts, casting services available

All three parts are from Dongguan Xinqida, made of stainless steel or titanium alloy.

The following is a breakdown of their characteristics:

Appearance and Structural Features

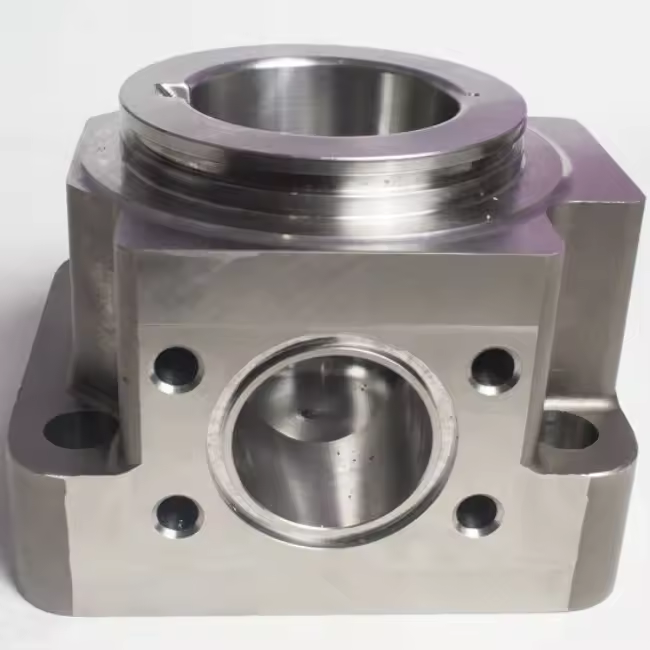

1. The first one has a hexagonal main structure with a large circular opening at the top and multiple bolt holes distributed around it, likely used for installing seals or securing other components.

There are also multiple holes on the side, likely for fluid inlet and outlet, sensor installation, or cable insertion. These design features suggest it may function in medical devices to connect, contain, or control fluids.

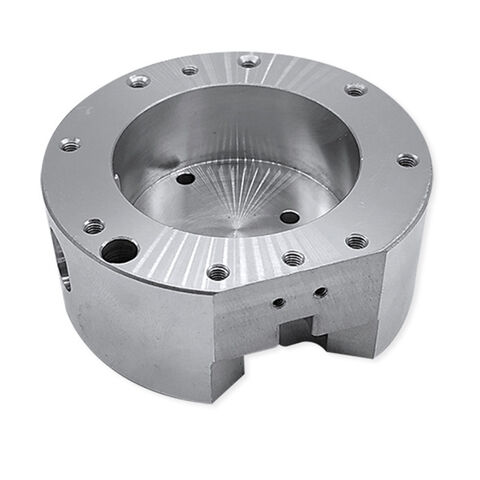

2. The second one is cylindrical in shape, with a large circular opening at the top. The interior shows some signs of machining, such as radial textures, possibly to increase friction or facilitate cleaning.

Multiple bolt holes are distributed around the circumference, indicating that it could be fixed to other components. Several notches and additional holes on the bottom may have been used to mate with other structural components for positioning, support, or to achieve specific functions, such as a container base for samples or liquids in medical equipment.

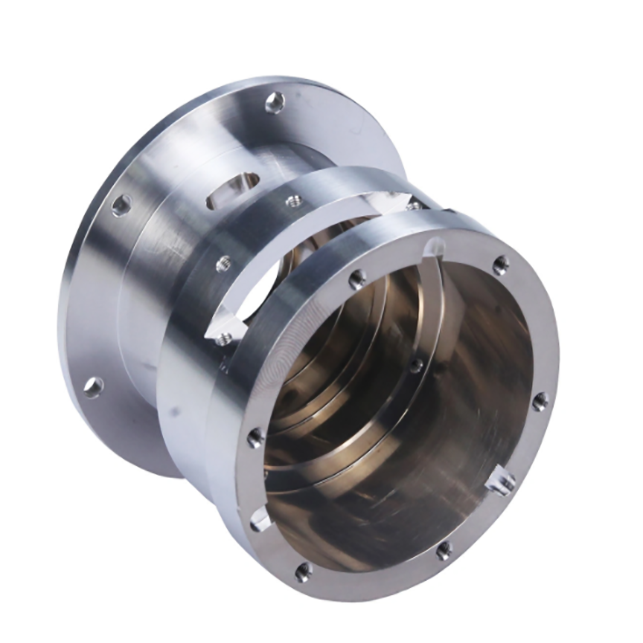

3. The third one has a more complex appearance, with multiple layers and holes of varying shapes. A threaded circular opening at the top may be used to tighten or remove a sealing cap or other component.

The main body has a large circular through-hole surrounded by multiple smaller holes, likely used for mounting fixtures, sensors, or fluid distribution. The side support structures suggest it may need to withstand certain pressures or maintain a stable connection to other components. It is speculated that it may be a key component in medical equipment, such as a pump body or valve seat.

Possible Medical Application Scenarios

1. Fluid Management Systems:

The multiple holes and connection structures on these parts make them suitable for application in medical devices' fluid management systems, such as infusion pumps, blood dialysis equipment, etc., for controlling the flow, distribution, and storage of liquids or blood.

2. Sample Processing Equipment:

In sample analysis and detection equipment, these parts can serve as sample containers, sample transfer channels, or fixed and connecting components of sample processing modules, ensuring the safety and accuracy of samples during the processing.

3. Mechanical Structure Components of Medical Devices:

Their robust structure and precise machining also make them suitable as part of the mechanical structure in medical devices, such as fixed bases for surgical instruments and joint connectors for medical robots, providing stable support and precise motion control.

Advantages of Material Selection

1. Stainless Steel:

It has good corrosion resistance and can withstand the corrosion from common disinfectants and bodily fluids in medical environments, ensuring the lifespan and safety of the parts. At the same time, stainless steel has high strength and hardness, able to endure certain pressures and mechanical stresses.

2. Titanium Alloy:

Lighter than stainless steel, with high strength and good biocompatibility, it does not cause immune reactions in the body, making it very suitable for medical devices that come into contact with human tissue, such as implanted medical devices or external medical device parts that directly contact patients.

Contact Us

Technical Support: +86 150-1532-6863

Email: cassy@xqdmachining.com

Website: https://xqdmachining.com/index.html