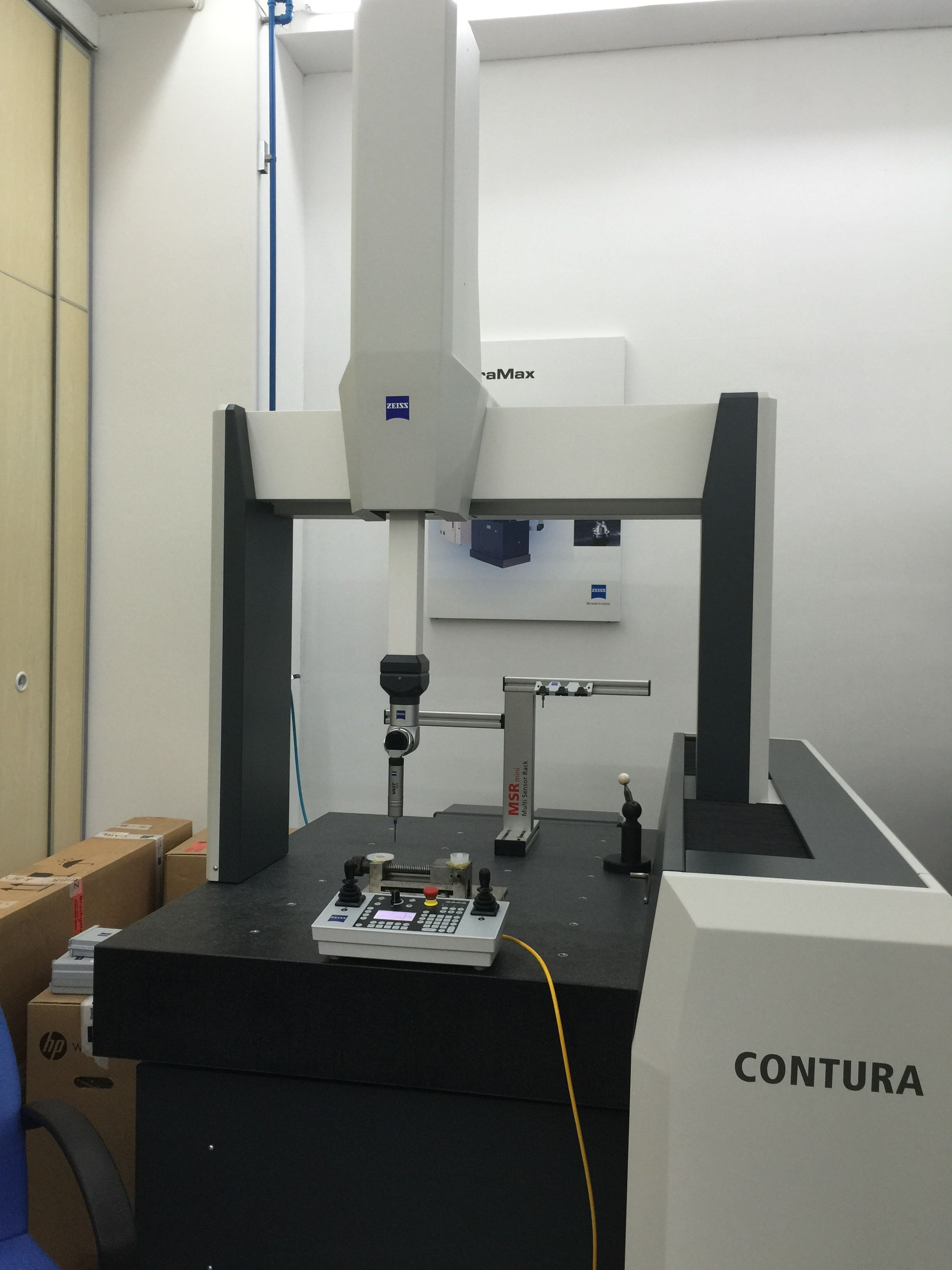

Exciting news! Zeiss coordinate measuring machines are officially in place, injecting new momentum into the company's precision machining business.

Today, the company welcomed a "high-precision partner" – the official use of the Zeiss three-coordinate measuring machine. This is not only an important measure for the company to upgrade equipment and enhance capabilities in the field of precision manufacturing, but also marks a key step in our pursuit of product quality perfection and the intelligentization of production processes.

As a benchmark equipment in the global precision measurement field, Zeiss's coordinate measuring machine is renowned for its measurement accuracy at the micrometer and even nanometer level. It can perform comprehensive and three-dimensional precise inspections of size parameters, shape tolerances, and geometric tolerances of precision hardware components. Even the slightest deviation in a hole diameter or the contour accuracy of complex workpieces can be accurately captured. This means that starting today, every product we manufacture will undergo a more rigorous and scientific 'quality control' before leaving the factory, providing customers with more reliable precision components that meet design standards.

While improving quality, the efficiency of Zeiss coordinate measuring machines will also press the "accelerate button" on the production process. Previously complex inspection processes required a lot of time, but the new equipment, with its automated measurement path planning and fast data processing capabilities, can significantly shorten time in initial inspections and batch sampling, reducing production waits caused by inspection delays, and making the entire processing flow smoother and more efficient.

More importantly, its integration will push the company further towards 'smart manufacturing.' The equipment can seamlessly connect with our digital production management system, enabling real-time transmission and analysis of measurement data. This helps technicians quickly identify potential issues in production, promptly adjust process parameters, reduce rework and scrap rates from the source, lower production costs, and also provides precise data support for technological innovation.

The arrival of the new equipment is a practice of the company's philosophy of "pursuing excellence" and a strong response to customer trust. In the future, we will fully leverage the technical advantages of the Zeiss coordinate measuring machine to continuously improve product precision and production efficiency, while continuing to deepen our efforts in the field of precision hardware processing, facing new challenges and opportunities with higher quality products and services!