Products Description

Professional high-precision processing of aluminum parts for aerospace services.

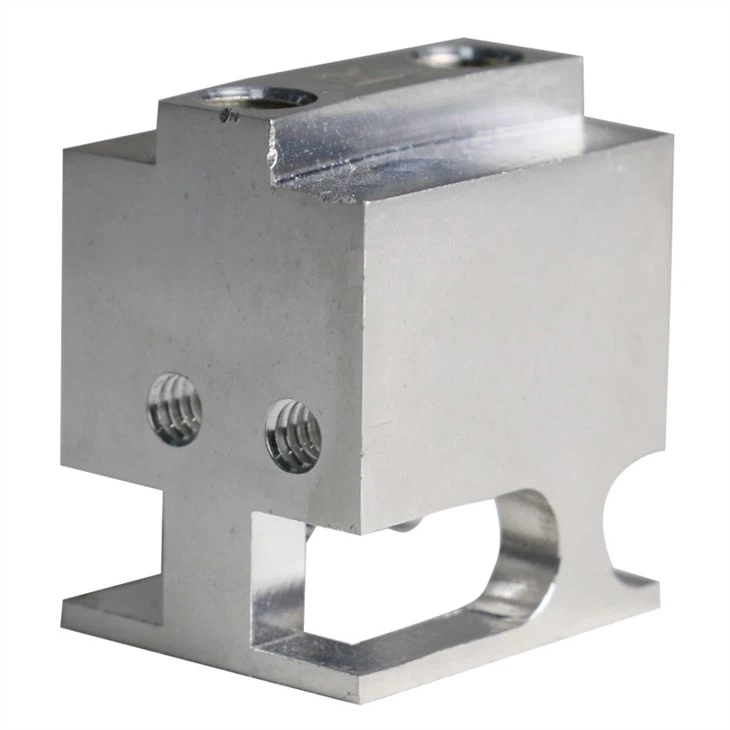

These three are common metallic machining parts in the aerospace field, made of aluminum alloy (a lightweight, high-strength alloy commonly used in aerospace).

The following is an analysis of their characteristics:

1. Structural and Functional Speculation

They are manufactured through machining processes such as milling, drilling, and boring, and they feature high-precision holes and grooves on their surfaces, which are used for structural connections, positioning support, or power transmission in aerospace equipment. They need to meet the requirements of lightweight, high strength, and high precision fit.

For example, parts with long grooves and multiple holes may be used for the integrated installation of complex mechanisms; square parts with through holes can serve as fixed bases for shafts and rods; irregular structural components can meet the connection demands of special spatial layouts.

2. Value in Aerospace Scenarios

Lightweight: The aluminum alloy material effectively reduces equipment weight, aligning with the aerospace needs for weight reduction and improved load efficiency.

Reliability: Precision machining ensures dimensional accuracy and fit, guaranteeing structural stability under extreme conditions such as vibrations and high pressures, thus avoiding risk of failure.

Modularity: Standardized machined parts facilitate quick assembly, maintenance, and replacement, enhancing the production and operational efficiency of aerospace vehicles.

Contact Us

Technical Support: +86 150-1532-6863

Email: cassy@xqdmachining.com

Website: https://xqdmachining.com/index.html

![]()