Why is cutting fluid important for effective CNC machining?

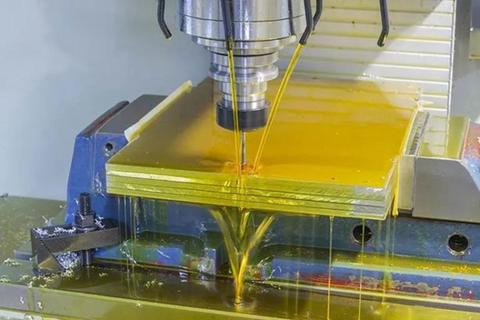

In CNC (Computer Numerical Control) machining, cutting fluid (also known as coolant or cutting oil) is by no means an optional accessory; rather, it is a core element that directly determines machining efficiency, workpiece quality, tool life, and even equipment stability. Its importance stems from the multiple critical functions it performs during the cutting process, directly addressing the high precision, high speed, and high repeatability requirements of CNC machining. The following details its necessity from six core dimensions:

1. Cooling effect: controls temperature and prevents heat damage

In CNC machining (especially milling, turning, drilling, etc.), the metal contact area between the cutting tool and the workpiece generates extremely high heat due to intense friction and plastic deformation (with local temperatures potentially reaching 800-1200°C instantaneously). The primary function of cutting fluid is to remove heat through convection, conduction, and evaporation, achieving the following objectives:

Protecting workpiece accuracy: High temperatures can cause thermal expansion of the workpiece, disrupting the CNC preset machining dimensions (for example, the tolerance of precision parts may be as small as 0.001mm), and insufficient cooling can directly lead to dimensional deviations.

Prevent surface burning of workpieces: Excessively high temperatures can cause oxidation and discoloration on the surface of workpieces (such as the 'blue spots' in stainless steel processing), and may even alter the microstructure of the surface layer (such as annealing of quenched parts or hardening of soft materials), thereby damaging surface quality.

Stable machining environment: Prevent heat from transferring to key components such as the machine spindle and guide rails, avoiding equipment deformation due to heat that could affect motion accuracy (e.g., spindle thermal elongation leading to Z-axis positioning errors).

2. Lubrication: Reduces friction and extends tool life

The friction between the tool edge, the workpiece, and the chips is the main reason for tool wear (such as flank wear and edge chipping) and increased cutting resistance. The lubricating components in the cutting fluid (such as extreme pressure agents and oily agents) can form a physical or chemical lubricating film on the contact surfaces, achieving:

Reduce tool wear: The lubrication film decreases direct friction between the cutting edge and the workpiece, significantly extending tool life (for example, in milling operations using cutting fluid, tool life can be increased by 2-5 times), reducing the frequency and cost of tool replacement.

Reduce cutting resistance: Reduced friction lowers cutting force by 10%-30%, not only saving machine tool energy consumption but also preventing tool vibration (chatter) caused by excessive cutting force, thereby improving the surface finish of the workpiece (Ra value can decrease by 1-2 grades).

Prevent chip adhesion to the tool: For sticky materials such as aluminum alloys and stainless steel, insufficient lubrication can cause chips to stick to the cutting edge or chip groove of the tool, forming a "Built-Up Edge" (BUE). A BUE can scratch the workpiece surface and even lead to tool chipping, whereas cutting fluids can effectively inhibit the formation of a BUE.

3. Chip removal: Clears chips to prevent secondary cutting.

In CNC machining (especially deep hole drilling, blind hole milling, and cavity machining), if chips cannot be removed in time, it can cause serious problems:

Avoid secondary cutting: Residual chips may be cut again by the tool, causing surface scratches on the workpiece, reduced dimensional accuracy, or even chipping of the tool edge.

Prevent chip clogging: In deep hole machining, chip accumulation can block the chip removal channel, causing the tool to overheat or break, or damaging the workpiece due to excessive pressure (such as deformation of the hole wall).

Chip removal method: The cutting fluid flushes chips out of the cutting area through high-pressure injection (CNC machine tools are usually equipped with high-pressure cooling systems, with pressures reaching 20-100 bar), ensuring a clean machining area.

4. Anti-rust effect: protects workpieces and equipment, reducing maintenance costs

Workpieces processed by CNC (mostly metals such as steel and aluminum alloys) and machine tool components (spindles, guides, fixtures) are easily exposed to air, moisture, and chemical components in cutting fluids during processing. Without rust protection, this can lead to:

Workpiece Corrosion: If semi-finished products are not treated in time after processing, the residual moisture and metal debris on the surface can cause corrosion (such as red rust on steel parts or white spots on aluminum alloys), leading to direct scrapping or increased subsequent polishing costs.

Equipment Corrosion: Rust on precision components such as machine tool guideways and spindles can compromise motion accuracy and increase maintenance difficulty and costs (for example, rusted guideways need to be re-ground, which is expensive).

Rust Prevention Mechanism: Rust inhibitors added to the cutting fluid (such as nitrite substitutes or organic amines) form a dense protective film on the metal surface, isolating it from water and oxygen, effectively inhibiting corrosion (cutting fluids typically require a rust prevention period of ≥7 days for steel parts).

5. Improve surface quality: meet the requirements of precision machining

CNC machining often requires high precision (such as IT5-IT7 tolerance levels) and high surface finish (such as Ra≤0.8μm). Cutting fluids directly affect surface quality in the following ways:

Reduce friction scratches: The lubricating film prevents direct friction between the tool and the workpiece surface, reducing microscopic scratches.

Inhibiting built-up edge: As mentioned earlier, built-up edge can cause 'fish scale patterns' or scratches on the workpiece surface, and the lubricating effect of cutting fluid can effectively prevent its formation.

Stable cutting state: Cooling and lubrication work together to reduce tool vibrations (chatter) and prevent surface ripples caused by vibrations (such as 'tool marks' after milling).

6. Ensure stability and safety in processing

Stable cutting process: The cutting fluid maintains stable cutting force and torque by controlling temperature and reducing friction and vibration, preventing CNC machine tool 'stalls' or program interruptions due to load fluctuations.

Improve the working environment: Compared to the large amounts of metal dust (which can harm operators' respiratory systems) and irritating fumes produced by dry cutting (such as aluminum dust from dry cutting aluminum alloys and high-temperature fumes from dry cutting stainless steel), cutting fluids can suppress dust and fume generation, enhancing operational safety.

Summary: The Impact of Cutting Fluids on the 'Cost-Efficiency-Quality' of CNC Machining

If cutting fluid is neglected or used improperly (such as too low a concentration or incorrect selection), it can lead to a series of chain reactions:

Shortened tool life → increased replacement frequency → higher processing costs;

Workpiece accuracy out of tolerance → higher scrap rate → decreased production efficiency;

Equipment corrosion/wear → increased maintenance costs → shortened machine tool lifespan.