About Us

Dongguan Xinqida Precision Hardware Accessories Co., Ltd.

Hong Kong Qida Hardware Machinery Co., Ltd.

Dongguan Xin Qida Precision Hardware Accessories Co., Ltd. is headquartered in Dongguan, with a branch in Hunan named "Changsha Daqi Intelligent Equipment Co., Ltd." It is a company specializing in providing intelligent manufacturing solutions for precision hardware components.

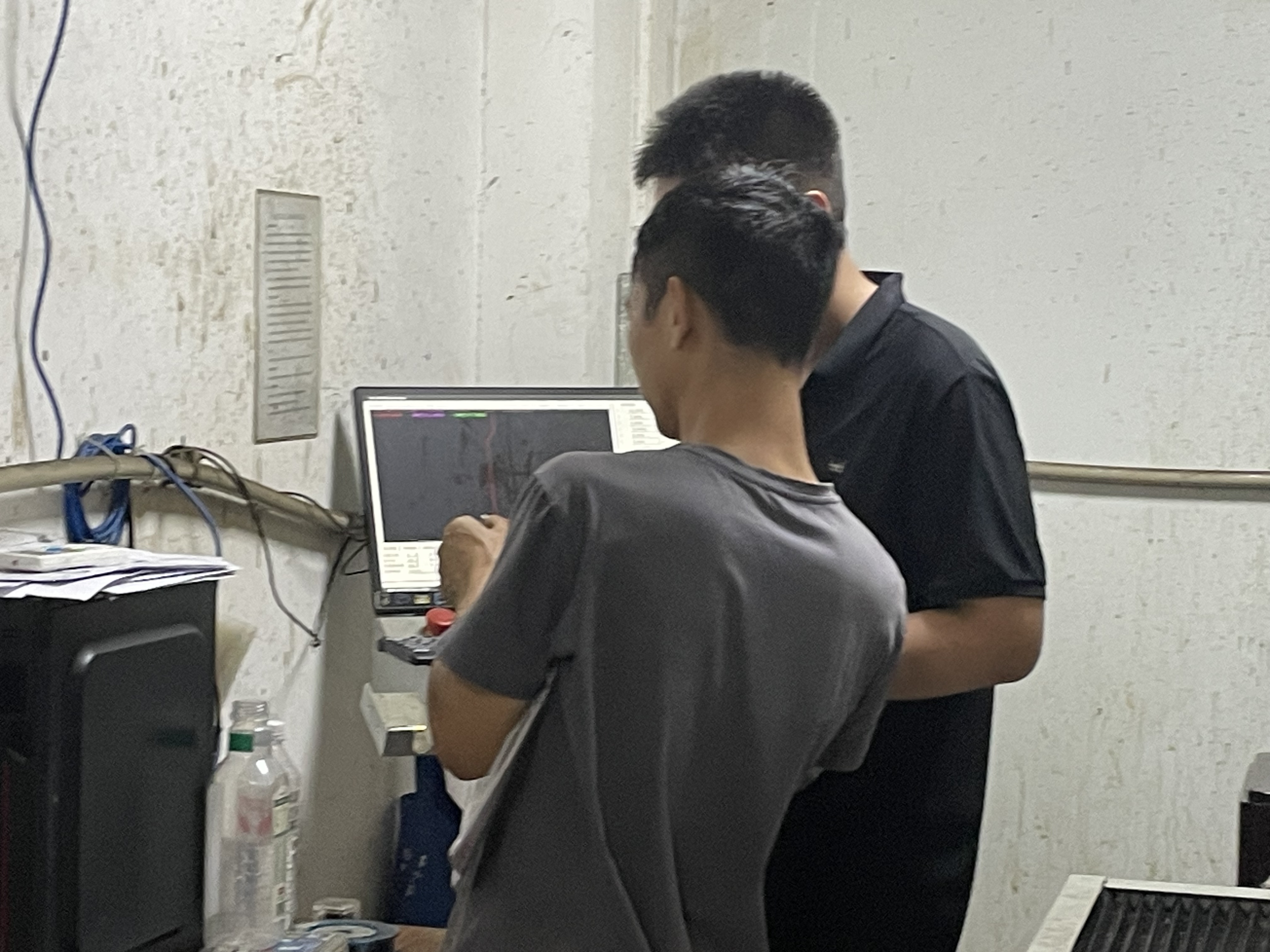

Currently, Xin Qida owns more than 80 high-precision and advanced equipment machines, with a production team of over 50 employees, including more than 40 senior technical talents. The company has also established talent delivery plans with several technical schools and training centers.

The main business of the company involves the processing of precision hardware components for various industries such as aerospace, medical, optics, semiconductor, and automotive sectors. Xin Qida has a digital management system (ERP), and a well-established scientific management system that provides customers with information security and guarantees in delivery cycles. Every production process at Xin Qida strictly complies with the ISO9001:2015 quality management system, effectively ensuring product performance and quality.

Xin Qida has always adhered to the corporate tenet of "valuing quality, being honest, and taking responsibility," with the business philosophy of "customer first, winning with technology, valuing efficiency, and excelling in service." Guided by the "Four Excellence" operating principles of "meticulous management, superb technology, profound culture, and capable team," the company has rapidly grown into a leading enterprise in the precision hardware component manufacturing industry.

Over the past 20 years, Xin Qida has served hundreds of clients, with 80% of them being well-known enterprises in the industry (witnessed by clients such as Comba Telecom, Sanyo, Jun Kai, Duracell, Han's Laser, Haichang Intelligent, Liyuanheng, Mitsubishi Heavy Industries, Dingtai, etc.), earning unanimous praise from customers.

Xin Qida will continue to improve its technological capabilities and service quality in the field of precision hardware component manufacturing, combining strict scientific management systems for sustainable development, ensuring client protection, achieving win-win cooperation, and creating a better future together!

Make your needs or requests

Let us contact you

Contact us -

9Y

Happy Clients

-

1880+

Sign a contract

-

24H

After-sales service

-

38+

Win awards